FUGAKU THE ULTIMATE PORTABLE AUDIO SYSTEM

THE ULTIMATE LISTENING EXPERIENCE WITH UNMATCHED BASS AND CRYSTAL CLEAR SOUND SEPARATION

overview

THE WORLD'S FIRST "MEMS HYBRID EARPHONES + DEDICATED FULL ANALOG PORTABLE AMPLIFIER + DEDICATED 16-CORE CABLE" ULTIMATE PORTABLE AUDIO SYSTEM

Earphones

◆ PVD black coated pure titanium housing

◆ Ear hook structure for increased wearing stability

◆ 8-driver 5-way configuration

Ultra-high range: MEMS speaker x1

High-range: BA driver x2

Mid-range: BA driver x2

Mid-low range: BA driver x1

Low range: Φ8mm dynamic driver x2

◆ Wideband frequency response over 100kHz

◆ Multi-amplifier connection with original 7-pin connector

◆ Crossover circuit concentrated on the amplifier side

Dedicated portable amplifier

◆ 2-story structure with 4-layer board (power supply) + 8-layer board (amplifier)

◆ Electronic volume MUSES72323 adopted

◆ Active crossover circuit with 10 channels in total for left and right

◆ Power amplifier circuit with 12 channels in total for left and right

◆ Driving method

BA&MEMS: Single-ended drive

Dynamic driver: Balanced drive

Dedicated cable

◆ 16-core pure silver original cable

◆ Specially designed Ultimate grade high sound quality processing

THE BIGGEST FEATURE OF FUGAKU

It is a three-type hybrid driver and a full analog multi-amp system.

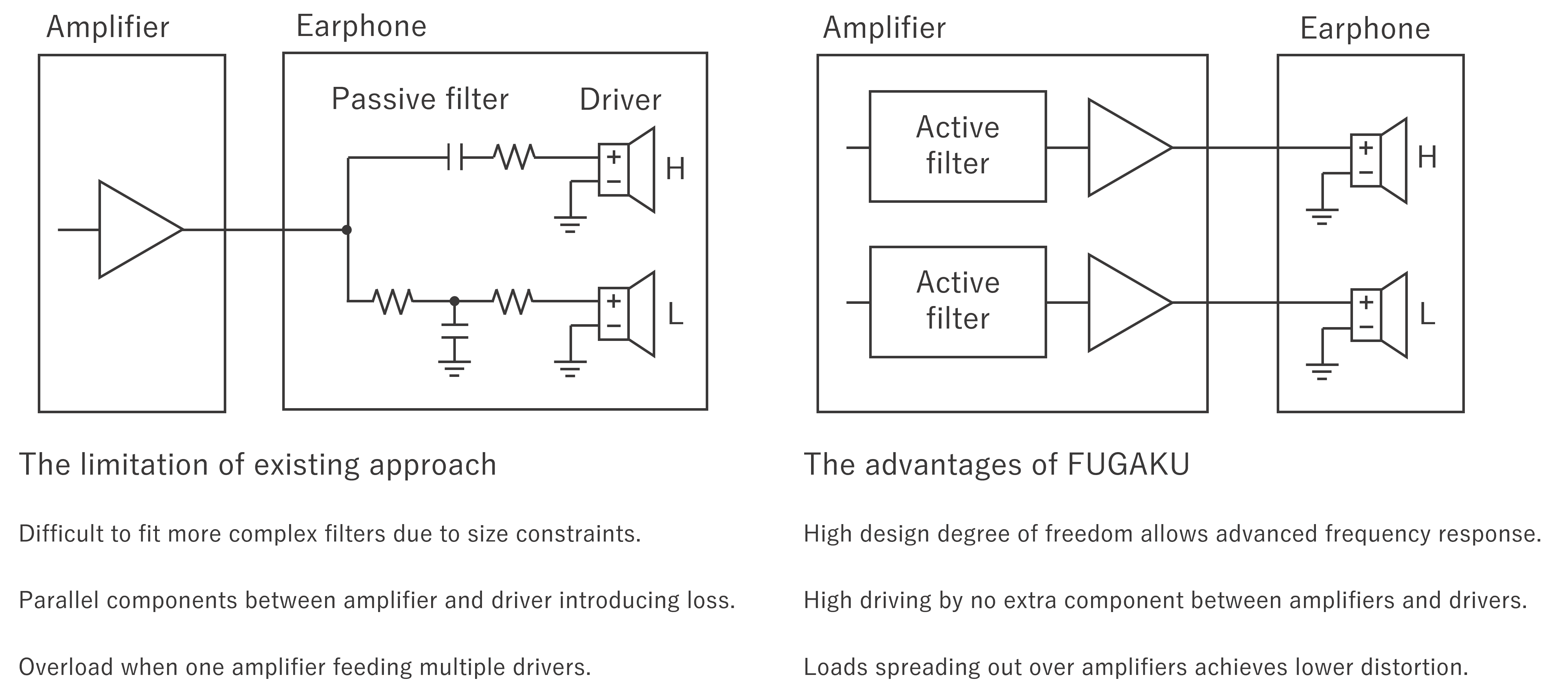

The diagram below shows a simplified example of the conventional system on the left, and the FUGAKU multi-amp system on the right.

The conventional system uses the order Amplifier → Passive Filter → Driver, whereas

the FUGAKU system uses the order Active Filter → Amplifier → Driver.

In the conventional method, there is a passive filter between the amplifier and the driver for band division, so the amplifier cannot drive the driver directly, and the sound loses a direct feeling.

In the conventional method, there is a passive filter between the amplifier and the driver for band division, so the amplifier cannot drive the driver directly, and the sound loses a direct feeling.

In addition, the passive filter needs to be small to fit into the housing of the earphone, resulting in a simple design.As a result, it becomes difficult to make the frequency characteristics ideal for the designer.

In addition, since one amplifier drives multiple drivers, the impedance becomes lower as the number of drivers increases, and the load on the amplifier becomes high and it is prone to distortion, so there are several negative factors in terms of sound quality in exchange for versatility.

To overcome these, FUGAKU adopted a multi-amplifier method. This is a method that has existed in the speaker world for a long time.

First, the band is divided, and then each driver is driven by an amplifier prepared for each band. It is the world's first hybrid driver earphone and full analog multi-amp configuration. It is no longer necessary to fit a filter in the earphone housing, and it is possible to use an advanced active filter composed of an OPAMP.

As a result, it is possible to assemble even high-order steep filters, and it is possible to freely design the frequency characteristics that most affect sound quality. In addition, since it is possible to use a large amount of high-quality parts with large volumes such as film capacitors, it is possible to improve the quality of each part.

Not only that, but because the amplifier and driver are directly connected, the driving force is high, and a sound with a direct feeling that has never been heard before can be achieved.

As the number of drivers increases, the number of amplifiers also increases, so the load per amplifier is lighter and less likely to distort, which is an advantage.

The expected disadvantages of this method are the reverse of the advantages of the conventional method.

Since a dedicated amplifier and a dedicated multi-pole cable are required, versatility is reduced and costs increase, but we adopted this method because we thought that the benefits in sound quality far outweigh the disadvantages.

With the multi-amplifier method for speakers, it is necessary to prepare a preamplifier, active filter, and multiple power amplifiers separately, but FUGAKU is a product that contains these in a single housing, providing the ultimate sound with a sense of scale equivalent to the combination of a conventional player and portable amplifier.

Product Concept

FUGAKU started out as an "ultimate earphone" that only Brise Audio could make.

And if we were going to make it, we wanted to realize it with the quality that we most wanted, with sound quality as our top priority, and with a configuration that was not bound by existing frameworks.

When thinking of a unique configuration that would be advantageous in terms of sound quality, the idea of bi-amp driving with a dedicated portable amplifier first came to mind.

However, since we are able to develop everything in-house, we thought that we could make something even better by integrating the band division into the portable amplifier, and so the multi-amp system FUGAKU was born.

In FUGAKU, "quality" is divided into three categories: "sound quality," "design," and "convenience," and in order to realize all of these at a high level, we have made various efforts in the earphones, dedicated portable amplifier, and dedicated cable.

The sound quality we aim for is consistent in FUGAKU, with "expressing all the information from the source without leaving anything behind." The sound quality that is achieved by appropriately using multiple types of drivers, the excellent physical characteristics of the optimal structural design, and the sound quality directly driven by a high-performance band division circuit and multiple high-output power amplifiers overturned our common sense and left a strong impact that we had never experienced before.

Earphones

These earphones combine traditional drivers, dynamic and balanced armature, with new drivers, MEMS speakers, at a high level.

Since the dedicated portable amplifier has an active crossover built in, there is no crossover circuit inside the earphone housing, and each driver and amplifier are directly connected. The excellent physical properties of the three-dimensional sound guide tube, titanium stem, and gold-plated OFC ring integrally molded in the 3D printer driver unit holder, and the optimal parameter setting of the active crossover, have achieved acoustic characteristics that connect smoothly across the entire frequency range.

Based on many years of experience in the design, development, and manufacture of custom IEMs and universal IEMs, we have created a housing shape that is excellent in fit and sound insulation.

By using an ear hook type with the cable coming out from the bottom, we have suppressed the misalignment in the rotation direction, achieving extremely high wearing stability despite being a universal earphone. A specially designed 7-pin is used to connect the cable. Although it is a small multi-contact, it has a design that is in harmony with the earphone housing and has a sense of unity.

Dedicated portable amplifier

This is a portable amplifier dedicated to FUGAKU that combines compactness and usage time while putting a lot of material on the priority of sound quality.

Based on the feedback obtained from TSURANAGI, the differential line receiver and electronic volume have new circuits, the power amplifier has been brushed up and new circuits have been adopted, and after extensive evolution, it has been equipped with an active crossover and developed into a multi-amp.

In order to maintain convenience, the interior is implemented in three dimensions to achieve the same size as TSURANAGI. There are two main boards in a two-story structure, with the first floor being a four-layer board mainly for the power circuit and control circuit, and the second floor being an eight-layer board with only the analog circuit amplifier, with its functions separated. The main board is wired from the input and output terminals with pure silver wire, the same wire material as the dedicated cable.

A total of 10,000μF or more large-capacity capacitors are effectively placed in the power circuit, contributing to the sound quality with a low center of gravity.

In addition, 14 ultra-high-performance linear power circuits are implemented to thoroughly prevent interference between circuits.

Dedicated cable

This is a 16-core cable using pure silver conductors designed exclusively for this system to transmit the signal from the power amplifier to each driver without loss.

By using newly developed high-purity pure silver wire, we have achieved high flexibility, ease of use, and excellent sound quality despite the multi-core structure.

Based on the tuning method for pure silver wire cultivated by SHIROGANE, we have applied a special high-quality sound processing for the Ultimate grade.

EARPHONE FEATURES

Beautiful appearance and high wearing stability

Based on the experience of developers who have been engaged in custom IEM and earphone manufacturing for many years, FUGAKU's earphone part has created a housing design that combines comfort and beauty with industrial designers. The housing material is pure titanium, which is strong and has a moderate sound with few metal-specific quirks, and the surface is coated with PVD black to improve durability.

Based on the experience of developers who have been engaged in custom IEM and earphone manufacturing for many years, FUGAKU's earphone part has created a housing design that combines comfort and beauty with industrial designers. The housing material is pure titanium, which is strong and has a moderate sound with few metal-specific quirks, and the surface is coated with PVD black to improve durability.

Three slits representing the three pillars of the cable, amplifier, and earphones allow the gold-plated OFC ring that houses the dynamic driver to be seen, expressing the combination of black and gold, which are the corporate colors.

One of the major features of the appearance of this earphone is that it has an ear hook. However, if you use the so-called Shure-hanging method of hanging the cable over your ear, the weight of the cable may pull the earphones and cause them to shift in the rotation direction during use, or the cable may dig into the base of your ear and cause pain. To solve this problem, we adopted the ear hook system.

The cable is pulled downward, and the downward force is supported by a TPE ear hook to increase the stability of the fit. The ear hook has a built-in memory wire, and you can adjust the degree of bending.

In addition, because it is a multi-amplifier system, each amplifier output and each driver must be connected independently, but since there was no existing connector that was small and had 7 contacts and could be harmonized with the design of the earphone housing, we developed an original connector. The detachable cable structure is designed to allow replacement when the cable is broken and is not intended for customers to replace it themselves. The included earpieces are made of AZLA's XELASTECII, which has excellent fit and sealing properties.

One pair of each of the six sizes is included. In order to experience FUGAKU's excellent low-frequency expression, it is very important that there is a tight seal between the left and right sides, so please find the size that suits you.

Crossover and selection of the right driver for the right position

From our experience in manufacturing and developing custom IEMs and universal IEMs, we have determined that a 5-way split with low, mid-low, mid-high, high, and ultra-high frequencies is optimal for a well-balanced band division, such as the implementation scale and ease of creating good characteristics. The low frequency range is equipped with a Φ8mm dynamic driver that uses a liquid crystal polymer diaphragm. The two dynamic drivers are fixed facing each other on an OFC ring.

By using an opposing arrangement, unnecessary vibrations caused by the movement of the diaphragm can be canceled, and the load is distributed by two drivers connected in series, resulting in low distortion, good response, and a heavy low frequency range. In addition, this OFC ring is gold-plated to protect the surface and keep it smooth.

The mid-low frequency range is equipped with a single BA made by Sonion, and the mid and high frequencies are equipped with dual BAs made by Knowles, for a total of three types of 5BA drivers. A side-port type MEMS speaker made by xMEMS is used for the ultra-high frequency range.

The high responsiveness of the piezoelectric method and the wideband reproduction characteristics enhance the airiness, delicacy, and reality of the sound. It utilizes the inverse piezoelectric effect, in which a piezoelectric film deforms when voltage is applied, and produces sound by vibrating the piezoelectric film itself, which is made from a silicon wafer. Compared to DD and BA, which drive the diaphragm with electromagnetic induction from a coil, these devices are smaller and more responsive, and there is very little variation because there is no need to assemble mechanical parts.

Layout that achieves ideal frequency characteristics

Each driver is fixed to a driver unit holder (purple part) with an integrated sound guide tube made by a 3D printer and assembled into the housing. The sound coming out of the unit holder is combined into one at the stem part of the titanium housing to create the final sound.

Each driver is fixed to a driver unit holder (purple part) with an integrated sound guide tube made by a 3D printer and assembled into the housing. The sound coming out of the unit holder is combined into one at the stem part of the titanium housing to create the final sound.

The design of this unit holder and stem part aligns the phase of each driver, resonates the sound to adjust the peak and dip position, and creates the sound that is the base of sound creation using an active crossover. This is one of the important parts for realizing the three-dimensional sound of FUGAKU, and it took repeated trial and error.

Because the MEMS speaker is small and thin, even if it is placed near the exit, it is easy to secure space for the sound guide tubes of other bands, and it was possible to optimally handle it. The OFC ring that fixes the two dynamic drivers is also connected to the sound guide tube of the thin tube low-pass filter structure of this unit holder.

In addition, sound-absorbing material is placed on the back side of each dynamic driver and inside the arm-shaped protruding part where the ear hook is attached. By absorbing and attenuating the sound emitted from the rear port of the dynamic driver and the rear vent of some BA drivers and reverberating inside the housing, we have reduced the impact that the sound would have on the operation of the diaphragm if it re-entered the housing, improving the clarity of the low range.

FEATURES OF A DEDICATED PORTABLE AMPLIFIER

3D structure that realizes compact size

The exterior is made up of three parts and a volume knob, as shown in the left figure. Only the top plate is made of forged carbon with a random pattern, while the rest is made of machined aluminum.

Forged carbon is a carbon material with a pattern different from twill and plain weave, which has been used in supercars in recent years. It was adopted to reduce weight and give a beautiful appearance. By placing the volume knob in the corner, there are no protrusions, and the sides of the volume knob are flat, making it less likely to cause accidental operation. In addition, the design is such that the screws are not visible from anywhere other than the bottom, and the appearance is also taken into consideration.

As for the internal structure, it is highly densely implemented, aiming for the same size as TSURANAGI, with consideration given to portability. The main board is two stories high, and the sub terminal board is located on the third and fourth floors. The second floor and the terminal board are wired, and pure silver wire is used for the same wire material as the dedicated cable.

The method of connecting the main board and terminal board with wiring has been inherited from TSURANAGI, but the intention is to prevent mechanical stress from being applied to the terminals. If everything is fixed rigidly, stress will be applied to the solder part of the terminals, and the solder will crack during use, causing poor contact.

The second floor board has a heat sink/shield case, and the sides of the shield case are thermally bonded to the aluminum housing with silicone rubber for effective heat dissipation. There is a flat area on the second floor board with no components, and this area is thermally bonded to the back of the shield case with silicone rubber.

The size is 3mm thicker than TSURANAGI, and 5mm shorter in the length direction due to the lack of protrusions, making the circuit scale more compact. From the right, the front has a 3.5mm unbalanced input, a 4.4mm balanced input, Rch output, and Lch output. The back only has a USB Type-C charging terminal. When viewed from above, there is a volume in the corner, and the power is turned on and off by pressing and holding the push button. To prevent scratches, Toray Ultrasuede is attached only to the bottom. There are small holes on the sides for heat dissipation.

Power supply configuration: Power supply circuits are thoroughly separated to prevent interference

There are 7 power sources per channel, for a total of 14 on both sides. The battery voltage is boosted and inverted by the dual power supply generation circuit, and a linear power supply circuit is placed at the rear to supply clean, noise-free power to the amplifier. The dual power supply generation circuit is divided into two, one for low voltage and high current, and one for high voltage and low current. This is because the electronic volume requires high voltage operation of ±10V or more, so they are set up separately.

If everything were to be operated at high voltage, the power consumption would be quite high, and the reduction in usage time and heat generation would be unrealistic, so this configuration was adopted.

In addition, the linear power supply circuit uses an ultra-high performance linear regulator that can remove even high-frequency noise, which was also used in TSURANAGI. Since a total of 14 of these are required, high costs are unavoidable, but this design is given top priority to sound quality.

The linear regulator is installed independently for each block of the amplifier circuit to prevent interference between circuits and improve the sense of separation and resolution of the sound.

Large-capacity capacitors are placed in various places to prevent the power supply from fluctuating when it flows from upstream to downstream. In addition, because there was not enough space to put a relay at the output of the amplifier for protection, another method of protection was required. In the FUGAKU amplifier, a switch is provided as a protection circuit to turn off the operation of the linear regulator and to short to GND in order to drain the charge of the large-capacity capacitor.

By shorting the power supply to GND the moment the power is turned off, the amplifier outputs a signal based on the power supply voltage, so if the power supply becomes zero, the output will also become zero. The protection circuit operates when the power is turned off normally, when DC leaks from the amplifier, the power supply circuit malfunctions, or when the inside becomes very hot. This protection circuit enables relay-less protection, making it possible to realize a palm-sized amplifier. In addition, because there is no relay at the output of the amplifier, the output impedance is low, allowing for more direct drive to the earphones.

Amplifier configuration: Low noise and distortion throughout

Based on TSURANAGI , this amplifier has been significantly improved by adding a crossover circuit and reviewing the circuit. The first improvement is that a low-pass filter has been placed in the first stage.

In TSURANAGI, the final stage power amplifier also served as a low-pass filter, but by placing it in the first stage, the overall noise has been reduced. In addition, since there is no longer anything limiting the bandwidth of the power amplifier, it also contributes to improving the responsiveness when driving earphones. The capacitor used in this low-pass filter is a special type called an X2Y capacitor, which is a well-matched combination of two capacitors specialized for processing balanced signals.

There is an IC in front of the low-pass filter that switches between unbalanced and balanced inputs, and all signals are input to the low-pass filter as balanced signals. This structure is the same as TSURANAGI, but by using a semiconductor switch with very low resistance and low distortion instead of a toggle switch, we have added a function to automatically select the input terminal along with a function to detect whether the terminal is inserted or removed. The differential line receiver is also a new circuit different from TSURANAGI, and what was previously a single IC has been split into two ICs to improve performance.

As a result, the residual noise here is less than one-fifth of that of TSURANAGI.

The electronic volume has also been updated to MUSES72323 manufactured by New Japan Radio. This improves the sense of air and freshness required for high-end equipment. The step size has also been halved from 0.5dB to 0.25dB, allowing for more precise volume adjustment.

The buffer amplifier is a FET-input OPAMP, which is used to minimize the current output by the electronic volume to minimize distortion, and to drive the crossover circuit, which has a large capacity capacitor. The power amplifier has a different configuration for the dynamic driver and others. A DC bias circuit has also been added to the power amplifier that drives the MEMS driver.

First, the power amplifier that drives the dynamic driver is a circuit that combines a fully differential amplifier and a current feedback amplifier in the same configuration as TSURANAGI, converting it into a balanced signal while driving it. The added bonus is that the components used have been reviewed to reduce output impedance and improve driving power. The power amplifiers other than the dynamic driver use a completely new circuit and a voltage feedback type amplifier. This is also designed to drive headphones and has an excessively high performance for earphones.

Although it is not shown in the diagram, in FUGAKU, a DC servo amplifier is incorporated into a non-MEMS power amplifier to eliminate AC coupling capacitors. The component constants of the DC servo amplifier have been reviewed and the feedback method to the power amplifier has been further simplified to achieve low noise with a small number of components. As shown in the block diagram of the power supply circuit earlier, an original low-noise circuit based on a linear regulator has been developed for the DC bias circuit for MEMS.

Board layout with thorough signal quality

The main board has a two-story structure, and four terminals connect the boards. The first floor board mainly contains the power supply circuit, charging circuit, protection circuit, and the microcontroller that controls them. Since the power supply circuit is the main function, the copper foil is twice as thick as usual to reduce the resistance. The power supply circuit is equipped with large-capacity capacitors of more than 3000uF in total, which are installed as much as possible to achieve a low center of gravity of the sound. Both main boards are double-sided, and the layout is designed to prevent interference from noise through space.

On the back of the first floor, there are switches that short the GND of the dual power supply generation circuit, microcontroller, charging circuit, and protection circuit, which are noise sources, to prevent noise from getting into the amplifier circuit. On the front of the first floor, there is a volume, linear regulator, large-capacity capacitor, and protection circuit comparator, and it is composed of analog circuits.

As with TSURANAGI, the AD converter and volume built into the microcontroller detect the position of the knob and send a control signal to the electronic volume. The sound signal does not pass through the volume that is turned by hand. A high-performance conductive polymer capacitor is used for the large-capacity capacitor.

The front of the second floor contains only the power amplifier, which generates relatively large amounts of heat among the amplifier circuits and is therefore fitted with a shielding case that also functions as a heat sink. The back of the second floor contains the circuits from the semiconductor switch to the crossover, with the functions clearly separated between the front and back.

The circuit board on the second floor is an eight-layer board, which is being used for the first time, with four layers allocated to different functions on the front and back, resulting in a structure that improves low impedance and noise resistance.

Essentially, the audio signal is placed on the inner layer, and the outer layer acts as a GND shield, resulting in wiring that is less susceptible to external noise. As with TSURANAGI, the power supply and GND are laid out so as not to have a common impedance, and the GND is consolidated at one point, connected to the chassis ground with a gold-plated screw.

Sound pressure trimming function: Left/right matching and target curve realization

In general earphones, matching between the left and right and matching of frequency characteristics have been achieved by selecting drivers, but this still increases costs and limits the degree of matching.

FUGAKU has a trimming function that ensures that even mass-produced products do not deviate from the target frequency characteristics. As a result, we have achieved a mismatch between the left and right and the target curve of within ±10%, ±0.83dB.

The power amplifier is configured as an inverting amplifier as shown in the figure on the right and is a circuit that allows you to freely set attenuation and amplification. Earphone drivers have different frequency characteristics depending on the type, but their efficiency also differs, so overall level adjustment is required for each band so that they connect smoothly when combined. The power amplifier is responsible for this level adjustment and has a function that allows you to fine-tune the driver level adjustment before shipping, which is the trimming function. Before incorporating the drivers into the earphones, we measure the acoustic characteristics of each driver alone and decide what kind of trimming to perform depending on the degree of variation.

SPECIALIZED CABLE FEATURES

A new 16-core pure silver wire developed exclusively for FUGAKU

This cable is for connecting an amplifier to earphones, and uses a new wire material different from our silver wire cable SHIROGANE. The material is the same, but the thickness of each wire is smaller, so even when bundled into 16 cores, it is practical and has a sufficient total conductor amount.

The reason for the 16 cores is that it is necessary to connect an amplifier independently to a 5-way earphone, so there are 2 cores for the dynamic driver because it is balanced drive, 4 cores for the BA and MEMS HOT, and 2 cores for GND. Although GND can be used with 1 core, 8 cores are more stable in terms of shape than 7 cores, and the BA and MEMS GND are separated to the earphone terminal to prevent a sense of confusion. In total, there are 8 cores on one side, and 16 cores for both sides.

In addition, the wiring inside the earphones is also made of pure silver Litz wire, and since there was no wire material that uses conductors that meet our standards and is easy to use as internal wiring, we developed it newly for FUGAKU.

For ease of assembly, we have prepared six coating colors.

The amplifier side also has a cable connecting the main board and the terminal board, but this is the same wire as the 16-core cable, and is unified with silver wire. Using a large amount of silver wire was difficult in the development of SHIROGANE, but it brings out not only the good points of silver but also its unique characteristics, so the high-quality sound processing inside the amplifier and the high-quality sound processing of the 16-core cable are of the ultimate grade tuned exclusively for FUGAKU. In the cable, materials are placed near the terminals and branching points to absorb and shield electromagnetic waves, static electricity generated when moving, and vibrations. We have several types of materials, and we adjust the final sound by the order and where to process them, which is high-quality sound processing. In portable amplifiers, such materials are attached to the electronic components.

FUGAKU Accessories

・1 pair of each of 6 sizes of earbuds (Sedna Earfit XELASTEC II)

・Earphone Case

・Storage bag

・USB charger

・Type-C USB cable for charging

・Serial Number Card

・Warranty

・Product manual